Careful

and properly built striking platforms are one major key

to predictable flake removal. Please note that one must

have an understand knapping "terminology" to

benefit from this article. Platforms have four basic components.

All four components must have the proper characteristics

for a flake to be removed predictably, and if it does

not, the struck flake (if any) WILL become undesirable.

Lets look at the platform's components and why each part

is so essential. You must understand that these four components

almost always have to be created from scratch. Rarely

are they just sitting there waiting for your eager billet!

These are also listed in the order they should be made.

The descriptions here are intended for bi-facial preform

stages but can be applied to spalls. Note that one must

be quite proficient with a pressure flaker before you

master percussion flaking. This is because great percussion

platforms start with good pressure flaking.

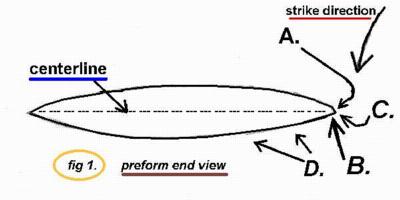

Now that

we have divided the platform into four parts, lets give

them all a letter code: "A", "B",

"C" and "D", as shown in fig. 1.

I will discuss the following topics relating to each

platform component.

1. It's purpose and/or function

2. "How to make them"

3. The attributes it should have

4. Trouble shooting... cause and effect of poorly made

and or Improperly prepared platforms

Part A

The first

we will look at is "A". This is the part commonly

referred to as the "bevel". The purpose of

the "bevel" is that it serves as the surface

that is actually struck to produce the flake. How do

we go about making the bevel? The most accurate way

is to use a SHARP pressure flaker. You can use a billet

to produce this on an early stage perform or spall.

It is highly recommended that you use a pressure flaker

to make this part. What attributes should part "A"

have? This part should have a bevel some where near

45 degrees. This angle can be changed by making another

"pass" or modifying angle of pressure. The

bevel should be smooth. What I mean by this is that

it should not contain irregular bumps, humps and micro

ridges. It should be just as if you used a router on

a piece of wood.

Part B

Part "B"

gives support to the strike. It is actually made from

part "A". There are many ways to make this.

The basic idea is that you're actually removing extremely

tiny chips off the bottom or underside of the "bevel".

(This is the same side the thinning flake will be removed

from.) Remember, your not really abrading the edge so

much as shaping it. Here's a couple ways of doing this.

The first way is to use a course abrader. Just rake

the edge downward gently and repeating this process

just long enough to feel less resistance as the abrader

is raked downward. You can also rake off these "micro"

flakes with the edge of your pressure flaker or use

a copper bar to do the same thing. Keep in mind this

is a very important step! If you rake it too hard or

use or use excessive force it will be too strong and

will greatly stress the stone upon striking it. Rake

thick performs harder than thin ones. If "B"

is not raked enough it will cause the platform to crush

or cause a step fracture very close to the edge. Too

much and you will break it! So don't over do it.

Part C

Moving

onto part "C". This part is also made from

"A". It is the polished area that your billet

actually strikes. It is better described as polished

but commonly referred to as abraded. Polishing sounds

so much more precise and civilized. To prepare this

part properly one must first have created "A"

and "B" flawlessly! You simply grind up and

down the platform edge. What I mean by this is your

grinding from base to tip. Another description of this

is if you're holding the preform flat, the grinding

motion is horizontal NOT vertical. A vertical motion

will destroy the platform. You want to use course abraders

for preforms thicker than 5 to 1 width to thickness

and a medium abrader for thinner bi-faces. Be cautious

not to over grind, this will also cause splits or breakage.

Keep in mind... the better you make your platforms...

the less grinding they will need!

Part D

Finally

part "D". This is what I like to refer to

as the "road" the flake will travel down.

This must be closely looked at before you decide to

remove any material for the purpose of platform construction.

If the surface area of part "D" is irregular,

then it must be corrected before an attempt at flake

removal is made. Simply put, don't waist the time and

circumference of your bi-face trying to chip off an

area with a stack or concavity. Just work on either

side of it. Build platforms to target areas with good

convexities. Stay away from concavities. You can modify

the surface of your bi-face by pressure flaking if necessary.

You must be careful not to cause "micro" steps

with your billet or Ishi stick. It will just be more

trash for your thinning flake to contend with.

Just remember to take your time and analyze. Be safe

and have fun!

- Mark

Bracken

Flintknappingtools.com

|